TIRES KILLED 7 THIS YEAR

Mequon doctor is victim; truck upkeep, corrosion are concerns

By RICK ROMELL

Posted: Nov. 10, 2007

The Mequon physician who was killed Thursday night by a wheel that came off a heavy truck is at least the seventh person to die in such an accident this year on the country's highways.

Three of the seven victims have been from Wisconsin.

The incidents are sometimes labeled freak accidents, but a University of Michigan safety expert says many stem from a common problem: Because of corrosion buildup on wheel parts, mechanics think they are tightening lug nuts correctly, but they actually are too loose.

"It's a very real problem, and it's a very serious problem," said John Woodrooffe, head of the safety analysis division at the University's Transportation Research Institute in Ann Arbor.

The latest victim is Krishna Chintamaneni, chief of staff at Wheaton Franciscan Healthcare-St. Francis. Chintamaneni, 55, was driving home on I-43 near Silver Spring Drive in Glendale when a tire flew off a southbound truck, bounced over a wall and hit Chintamaneni's windshield.

He died at the scene.

The truck driver didn't stop and may not have known what happened. Milwaukee County Sheriff's Department detectives continue to investigate.

The accident mirrors one March 16 that killed two University of Wisconsin-Eau Claire students traveling through Georgia on a spring-break trip. Fatally injured were Jason Buchmeier, 21, of Mauston and Jason Schluter, 23, of Lyndon Station.

The death toll there easily could have been higher. Six men were in the van that was struck, and it was climbing the median barrier - with the driver unconscious - when one of the passengers seized the steering wheel and guided the vehicle to safety.

With the van still traveling at 70 mph, 20-year-old Ryan Wirth said, he grabbed the wheel with one hand and used the other to hit the brake. Fellow passenger Patrick Senzig, whose screaming had roused the momentarily dazed Wirth, gave a similar account.

"I've never seen anything like that in my life," Senzig, 22, said of the truck wheel crashing into the van. "That's a tragedy no one should have to deal with, ever."

In terms of overall truck accidents, wheel separations are rare. A 1992 study by the National Transportation Safety Board estimated there were 750 to 1,050 a year, out of 349,000 truck accidents annually at the time.

But that amounts to roughly two to three a day, and the incidents were troubling enough in Ontario in the 1990s that the province passed a law imposing strict penalties on truck owners when wheels come off.

Besides the deaths in Georgia and Wisconsin, flying truck wheels have killed people this year in Indiana, New Jersey, Texas and the state of Washington. The Washington fatality came amid a spate of wheel separations over several months.

"We had it happen at least a half a dozen times, and it resulted in some pretty catastrophic collisions," said trooper Jeff Merrill, a spokesman for the Washington State Patrol.

"It's a problem," said Clayton Boyce, vice president of public affairs for the American Trucking Associations, the largest organization representing the trucking industry. "It's a maintenance problem, and it's certainly a tragedy that anyone was killed by this."

Boyce cautioned that the cause of the Milwaukee accident isn't known. It's possible the wheel involved didn't spin off an axle, he said. Rather, he said, it may have been the wheel was being carried on a truck bed and bounced off.

"We are very concerned about maintenance," Boyce said. "We have an entire section of ATA involved in maintenance issues."

Wheels also can be thrown from a truck when bearings seize because of a lack of maintenance, said Gerald Donaldson, senior research director with Advocates for Highway and Auto Safety.

After its 1992 study, the National Transportation Safety Board recommended that the trucking association take four specific steps to address wheel separations. The trucking group followed through in each case, safety board records show.

Woodrooffe said mechanics and drivers must be particularly careful about inspecting wheel nuts.

Typically, nuts are fastened with a specific amount of torque, or rotational force, which can be applied with a torque wrench, Woodrooffe said. Nuts must be tight, of course, but over-tightening can cause cracks.

The problem, Woodrooffe said, is that corrosion builds up on the fasteners over time. With the surfaces rougher, the torque wrench may show that the nut is appropriately tight when its actual holding power is half of what it should be, he said.

"That is a very, very disturbing result, because you have due diligence that's been complied with, but despite the mechanic's best efforts, unknown to him, the clamping force is not being achieved," Woodrooffe said.

Woodrooffe said he conducted his research as a private consultant on heavy-vehicle safety in Canada about five years ago, before joining the University of Michigan.

Heavy-truck wheels weigh 200 to 300 pounds, and when they spin off at highway speed, their velocity typically keeps them stable and rolling even when they hit a median, Woodrooffe said. That makes the likelihood of hitting a vehicle "fairly significant," he said.

And if the wheel crosses the median, "not only do you have to worry about the velocity of the tire, you also have to worry about the velocity of the vehicle coming in the other direction, so the energy of the collision is very, very high," he said.

Boyce said applying the correct amount of torque to lug nuts is indeed a key issue, as is corrosion.

"In the last 10 to 15 years, more and more, they've been using liquid corrosives to melt salt on the roads instead of the solid rock salt and other compounds," Boyce said. "These liquid ice melters stick to the undercarriage and the axles and the wheels of a truck much more readily than solid de-icers.

"Because of that, when they were first started being used, maintenance managers were shocked to see that trailers were wearing out and bolts were falling off after just a few years on the road."

He said materials have been improved as a result.

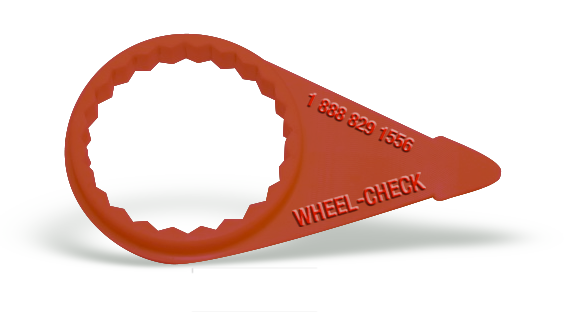

WHEEL-CHECK®: High visibility loose wheel-nut indicator

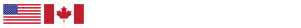

WHEEL-TORQUE: Red torque indicator used to mark a nut has backed off, and maintenance is aware of the problem

WHEEL-CHECK®, HIGH TEMPERATURE: Loose wheel-nut indicator that withstands higher temperatures

WHEEL-CHECK®, CUSTOM COLORS: Custom colors and sizes are available upon special request.

© All Rights Reserved. WHEEL-CHECK®, THE LOOSE WHEEL-NUT INDICATOR. "25 years helping roads to be safer."

*The use of Wheel-Check® in no way guarantees wheel-offs will NOT occur.