It is believed that vibration causes bolt loosening. By far the most frequent cause of loosening is side sliding of the nut or bolt head relative to the joint, resulting in relative motion occurring in the threads. If this does not occur, then the bolts will not loosen, even if the joint is subjected to severe vibration. By a detailed analysis of the joint, it is possible to determine the clamp force required to be provided by the bolts to prevent joint slip.

Often fatigue failure is a result of the bolt self-loosening which reduces the clamp force acting on the joint. Joint slip then occurs which leads the the bolt being subjected to bending loads and subsequently failing by fatigue.

Pre-loaded bolts (or nuts) rotate loose, as soon as relative motion between the male and female threads takes place. This motion cancels the friction grip and originates an off torque which is proportional to the thread pitch and to the preload. The off torque rotates the screw loose, if the friction under the nut or bolt head bearing surface is overcome, by this torque.

THERE ARE THREE COMMON CAUSES OF THE RELATIVE MOTION OCCURRING IN THE THREADS:

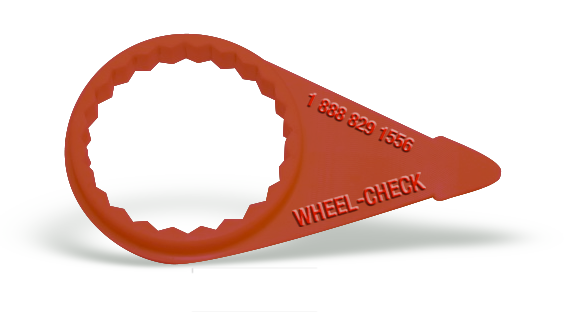

WHEEL-CHECK®: High visibility loose wheel-nut indicator

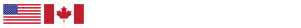

WHEEL-TORQUE: Red torque indicator used to mark a nut has backed off, and maintenance is aware of the problem

WHEEL-CHECK®, HIGH TEMPERATURE: Loose wheel-nut indicator that withstands higher temperatures

WHEEL-CHECK®, CUSTOM COLORS: Custom colors and sizes are available upon special request.

© All Rights Reserved. WHEEL-CHECK®, THE LOOSE WHEEL-NUT INDICATOR. "28 years helping roads to be safer."

*The use of Wheel-Check® in no way guarantees wheel-offs will NOT occur.