SECTION 392.7 OF THE FEDERAL MOTOR CARRIER SAFETY REGULATIONS

Landline Magazine, March, 2000

Per the rulebook, paperwork must record that an inspection has been done, but it does not prescribe the manner in which it shall be done.

Section 392.7 of the Federal Motor Carrier Safety Regulations states that "No commercial motor vehicle shall be driven unless the driver thereof shall has satisfied himself/herself that the following parts and accessories are in good working order … " It goes on to list such parts as brakes, steering, lights, tires and so forth.

In Section 396.11, it states that (a) Report required: Every motor carrier shall have its driver’s report, and every driver shall prepare a report in writing…on the same equipment listed in 392.7.

Section 396.13 states — before driving a motor vehicle, the driver shall:

(a) Be satisfied that the motor vehicle is in safe operating condition;

(b) Review the last driver vehicle inspection report; and

(c) Sign the report, only if defects or deficiencies were noted by the driver who prepared the report.

So, as everyone knows, paperwork must record that an inspection has been done, but it does not prescribe the manner in which it shall be done. That is left to the driver, although many fleet operations have pre-trip sequences and inspection checklists.

As an owner-operator, you are ultimately responsible for your own vehicle. And as many an owner has told me, "We know our trucks. Those rules were written for slip-seaters who jump in and out of company junk. My truck is my livelihood. I live with it, and I know everything that happens to it."

There's merit in that statement. If you curbed a tire, you know it happened. If you hit a particularly bad pothole, you know it.

You don’t wait for a pre-trip or a post-trip to check your own wheels or tires. You do it the next time you stop. At least you're supposed to. But things happen. At your next stop, all you can think about is checking the rest area's plumbing, and you forget to check your truck. Some pretty horrendous crashes have occurred because a driver had other things on his mind and forgot to check, or just assumed everything was OK.

I know better than to use this column to preach that everyone do a full 30-minute pre-trip inspection before and after every run. If I did, I’d deserve all the laughter and ridicule you’d heap on me. But I am trying to get you to think about what can go wrong on a truck, how long it takes to go wrong, and what might happen if and when it does.

Friends of mine recently had their brakes replaced. Their first set lasted about 430,000 miles. That's about two-and-a-half years the way they drive. Do you think they need to check those linings every day? The government might want them to, but it’s not realistic. How about once a month? That would give them an idea of how their brakes are wearing, with enough advance notice of when they need service. What about tires? They usually last a year or more. Would a monthly inspection make sense for them?

Hardly.

Tires are right out, well … where the rubber meets the road. We all know what happens when a tire suddenly loses air. It’s called a catastrophic failure. The result is bad for you (tire and road service costs), bad for motorists around you (flying debris, damage to vehicles) and bad for trucking’s image. Tire damage that can lead up to a catastrophic failure happens suddenly. One moment everything is fine. The next moment, you’ve driven over a nail that punctures your tread, or a pothole that cuts your sidewall. Pressure is lost, heat builds up, and the rest, as they say, is history. It may take time to happen, but you can be sure it will.

By now, you should get the idea. Some things go bad slowly. They should be checked regularly, but don’t need to be looked at daily. They just don’t change that quickly. Other things lead to problems that occur very quickly. Those are what you should look at daily, or more often if practical.

When doing your pre-trip inspection, first look at the condition of your tires. Proper inspection requires taking a flashlight and looking at the inside and outside sidewalls. You don’t need to crawl under the trailer, unless it’s a lowboy, high cube or some other specialized type. But you do need to look. Don’t forget to check in between each set of duals. A rock or concrete chip stuck in there can quickly damage flexing sidewalls.

Road debris or shock and vibration can damage air lines and fittings. Remember to listen for telltale hissing from under your truck. In a truckstop, you may have to get close to each fitting, so you can hear trouble over the noise from all those idling engines. Even though you may have listened for air leaks, it’s a good idea to pump down your brakes to make sure your system recovers air pressure rapidly. Air pressure recovery time is an indication of what condition your system is in, and leakage is taking place anywhere in the system.

Brake adjustment is still the most frequently found violation at roadside inspections, but with more and more trucks having automatic adjusters, it is becoming less of a problem by the day. Just remember to lubricate and check the adjusters when you do your regular maintenance.

Wheel-off accidents have gained more than their fair share of headlines lately. When wheels come off at highway speeds, people get hurt or killed. Wheels let go for several reasons. Loose lug nuts, cracked wheels and worn or damaged bearings are among the most frequent. You can check wheels and nuts quickly and easily by hand. One of the most frequent reasons lug nuts are loose is because they were over-tightened with an air impact wrench. Over tightening stretches the studs, reducing (not increasing) clamping force. That lets nuts back off. Final tightening should always be done with a torque wrench by hand. If your inspection finds one nut loose, chances are more will work loose on that wheel, and any other wheels hit by the impact wrench that day. You may have to replace the studs, too, if they’re found to be stretched.

Wheels can come off due to spindle and hub problems. Hubs that leak will show oil streaks on the wheels radiating from the hubs. If not detected early enough, oil could get onto brake linings, causing uneven braking or even skids. Wheel seals will leak if they are not seated correctly. Improperly installed seals may also skew bearings, causing axle scoring or premature bearing failure. These could cause a wheel assembly to fly off.

If you have a spring suspension, give it a quick look. You’re allowed one cracked leaf on most multi-leaf springs, but I’ve seen trucks come in with almost all of them broken. The idea of an inspection isn’t just to look at what’s wrong; it’s to get it fixed.

A few years ago, a friend told me what it’s like to get stuck in New York’s Holland Tunnel at rush hour, with a trailer sitting directly on its tires because a spring suspension let go. It’s not only embarrassing, it’s very, very expensive. Air suspensions are more durable because their failure mode is more gentle, and because they provide a better ride. Air bags wear gradually. You will probably hear a bag leaking before it lets go.

Check around your truck for critical items every time you stop. As items get less critical, schedule them for daily, weekly or monthly inspection. Be as thorough as you possibly can. The investment you’ll be protecting goes far beyond your rig and your load.

By the way, while we’re sharing these observations of what real drivers do in real situations, nothing said here should be taken as a recommendation to deviate from the procedures outlined in your little FMCSR book.

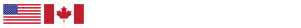

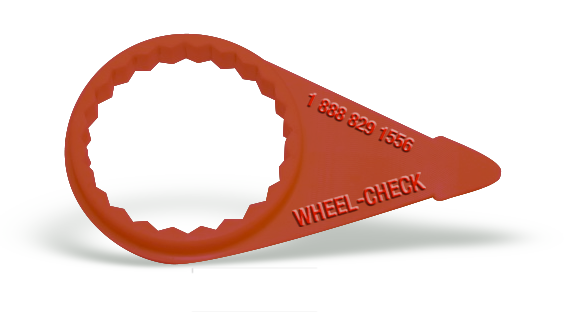

WHEEL-CHECK®: High visibility loose wheel-nut indicator

WHEEL-TORQUE: Red torque indicator used to mark a nut has backed off, and maintenance is aware of the problem

WHEEL-CHECK®, HIGH TEMPERATURE: Loose wheel-nut indicator that withstands higher temperatures

WHEEL-CHECK®, CUSTOM COLORS: Custom colors and sizes are available upon special request.

© All Rights Reserved. WHEEL-CHECK®, THE LOOSE WHEEL-NUT INDICATOR. "Over 25 years helping roads to be safer."

*The use of Wheel-Check® in no way guarantees wheel-offs will NOT occur.